REQUEST A QUOTE OR MORE INFORMATION

Feel free to reach out for any queries. We would be happy to help!

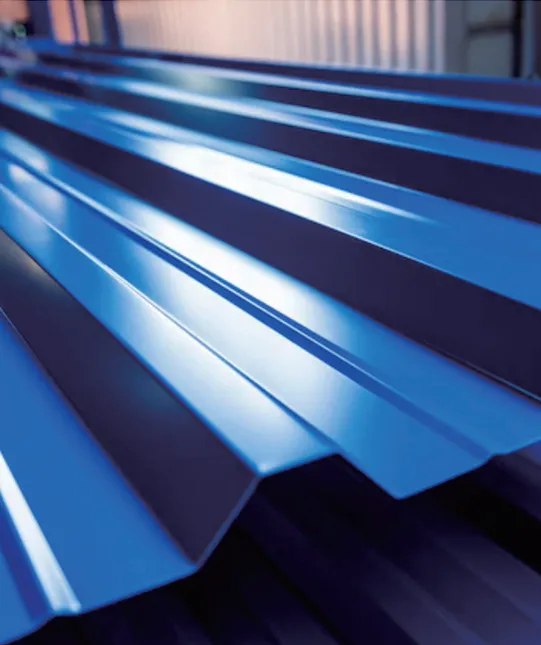

Gallery

We have provided professional products and solutions for metal packaging, automobile manufacturing, new energy vehicles, household appliances, wind power generation, railway construction and other fields...

Working at STEELHIGHSEN

We have provided professional products and solutions for metal packaging, automobile manufacturing, new energy vehicles, household appliances, wind power generation, railway construction and other fields...

Job Opportunities

We have provided professional products and solutions for metal packaging, automobile manufacturing, new energy vehicles, household appliances, wind power generation, railway construction and other fields...

Q&A

We have provided professional products and solutions for metal packaging, automobile manufacturing, new energy vehicles, household appliances, wind power generation, railway construction and other fields...

Download

We have provided professional products and solutions for metal packaging, automobile manufacturing, new energy vehicles, household appliances, wind power generation, railway construction and other fields...

Jul. 14, 2025

As the demand for high-performance coated steel continues to grow in construction, infrastructure, and manufacturing, Steelhighsen is proud to offer premium PPGI and PPGL products to global customers. These two materials are among the most widely used prepainted steel solutions in the market today—but what exactly sets them apart? And how should customers decide which one to use for their specific projects?

In this article, we explore the key differences between PPGI (Pre-painted Galvanized Iron) and PPGL (Pre-painted Galvalume), their performance characteristics, and how to choose the right option based on your needs.Explore Steelhighsen’s PPGI and PPGL product lines.

PPGI refers to pre-painted galvanized steel, which is made by coating a layer of paint on hot-dip galvanized steel. The zinc coating offers a barrier against rust and corrosion, while the paint layer adds color, aesthetic appeal, and additional protection.

Key Features of PPGI:

Excellent surface finish and paint adhesion

Moderate corrosion resistance (suitable for less harsh environments)

Cost-effective for roofing, wall panels, and interior applications

Easy to fabricate, bend, and cut

PPGL stands for pre-painted galvalume steel, made from a substrate of aluminum-zinc alloy-coated steel (typically 55% aluminum, 43.5% zinc, 1.5% silicon). This composition offers enhanced corrosion resistance compared to galvanized steel.

Key Features of PPGL:

Superior long-term corrosion resistance, especially in humid or salty environments

Higher heat reflectivity, contributing to energy efficiency in roofing

Longer lifespan, especially in coastal, industrial, or chemical-prone areas

Slightly higher cost than PPGI, but better long-term performance

| Property | PPGI | PPGL |

|---|---|---|

| Base Metal | Hot-dip galvanized steel | Galvalume (Al-Zn alloy-coated steel) |

| Corrosion Resistance | Good | Excellent (up to 3–6 times better) |

| Heat Resistance | Moderate | High |

| Paint Adhesion | Excellent | Excellent |

| Appearance | Smooth, bright colors | Slightly metallic, reflective surface |

| Cost | Lower | Slightly higher |

| Ideal Use | Indoor or mild outdoor environments | Harsh, coastal, humid, or industrial areas |

Choosing between PPGI and PPGL depends primarily on your project’s environmental exposure and budget.

Use PPGI if your project is located in a dry, moderate climate and cost is a major factor. It’s perfect for general-purpose buildings, warehouses, and interior panels.

Use PPGL if the structure will face harsh weather conditions, high humidity, coastal exposure, or chemical environments. Though it’s more expensive, the added longevity and protection can reduce maintenance and replacement costs in the long run.

View the full range of Steelhighsen’s products to explore options suited to your application.

With over a decade of experience in steel production and export, Steelhighsen delivers high-quality PPGI and PPGL coils with consistent specifications, color uniformity, and performance. All products undergo rigorous testing to meet international standards such as ASTM, JIS, and EN.

We provide:

Custom thicknesses and widths

A wide selection of RAL colors and finishes

Fast delivery and professional support

Technical guidance for material selection

Steelhighsen’s products are widely used in roofing systems, sandwich panels, fencing, garage doors, home appliances, and more.

Learn more about our brand at www.steelhighsen.com

Understanding the key differences between PPGI and PPGL helps you make the best choice for your project’s long-term durability and cost-efficiency. With Steelhighsen, you not only get access to top-tier prepainted steel products, but also a knowledgeable team ready to support your business goals.

Whether you are a distributor, contractor, or OEM manufacturer, Steelhighsen is your reliable partner in sourcing PPGI and PPGL with confidence.

REQUEST A QUOTE OR MORE INFORMATION

Feel free to reach out for any queries. We would be happy to help!